News

August 3, 2023

Refrigeration and Air Conditioning Africa (RACA) Journal recently published an article written by, Eamonn Ryan, titled "The Strangest Batteries: An Ice Maker that Chills a Building." The article explores an innovative ice maker system that stores energy as ice, providing sustainable cooling for large buildings. This groundbreaking technology includes EVAPCO's thermal ice storage, revolutionizing the cooling industry and reducing environmental impact. Click here to read the full article.

July 14, 2023

Engineered Systems Magazine, a leading publication in the field of engineering and building systems, proudly presents an in-depth article by Tyler Lee, a renowned expert from Chesapeake Systems, shedding light on the prevention of critical failures of evaporative cooling equipment. The article, titled "How to Prevent Critical Failures of Evaporative Cooling Equipment," delves into the vital importance of maintaining efficient cooling systems in industrial and commercial settings. Tyler Lee's extensive experience and expertise provide readers with valuable insights and practical solutions to

July 11, 2023

EVAPCO is the global leader in sizing and supplying certified cooling equipment for District Cooling Plants.

July 10, 2023

The need for cooling capacity is increasing globally. An expanding population and an evergrowing dependence on data increases the need for process cooling, centralized space cooling, and data center cooling. Meanwhile, in many places, water scarcity is a massive issue. In conventional, industrial cooling applications, the use of water for heat rejection is critical. Cooling towers and most evaporative fluid coolers depend heavily on water to reject waste heat to the atmosphere. Taking blowdown and drift losses into account, evaporative cooling systems use approximately three GPM per 100 tons

July 7, 2023

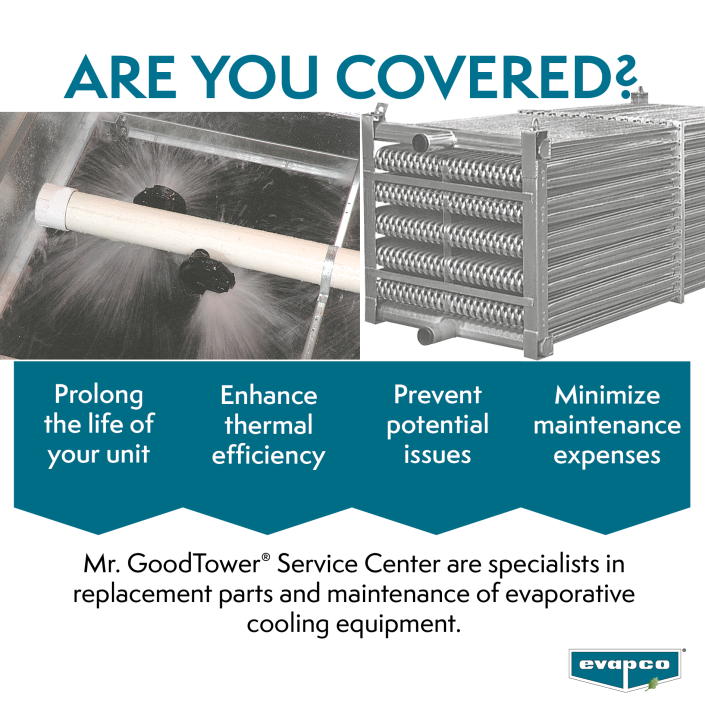

Mr. GoodTower® Service Centers are specialists in replacement parts and maintenance of evaporative cooling equipment.

June 15, 2023

Data centers rely heavily on the capability and optimal performance of heat rejection equipment being utilized to function efficiently. When conserving water is a primary goal, careful attention must be given to the heat rejection equipment being specified. Data center cooling applications can be served by either an open-loop cooling tower or a closed-circuit cooler. The requirements of the application, location of the facility, local utility costs, water availability, and environmental considerations are the primary factors when choosing between the two. Click here to read the full article.

May 5, 2023

We are thrilled to announce that our very own Troy Reineck, known as "EVAPCO's Professor," was one of the industry experts invited to share their insights on evaporative cooling in a comprehensive article published by ACHR News. The article emphasizes the growing significance of energy-efficient cooling solutions and explores the critical role evaporative cooling plays in achieving sustainability objectives. Several experts, including Troy Reineck, were asked to provide their expertise on the development, implementation, and benefits of evaporative cooling systems. During his interview

April 25, 2023

EVAPCO provides a full spectrum of global product solutions for the Commercial HVAC, Industrial Refrigeration, Power Generation and Industrial Process markets. View the full spectrum of EVAPCO products in our Global Product Catalog .

March 9, 2023

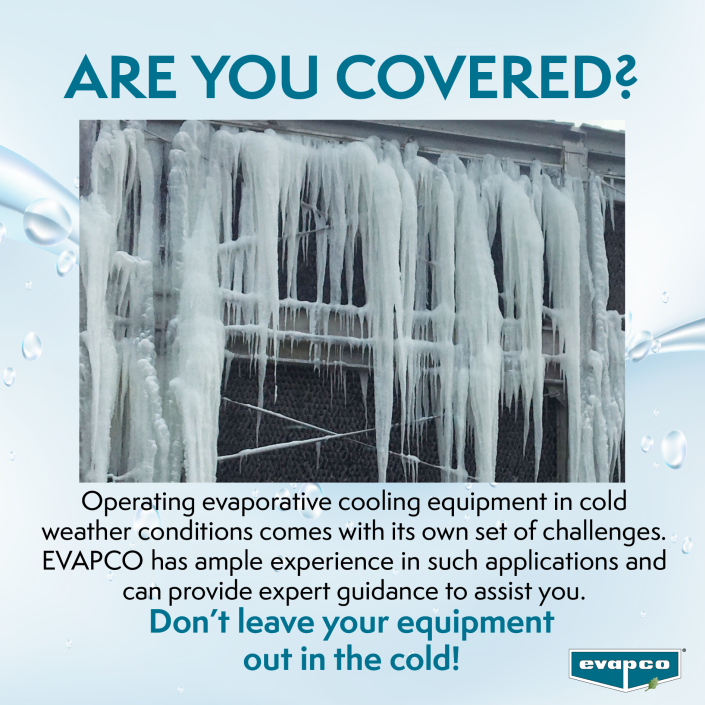

Don't leave your equipment out in the cold! Operating evaporative cooling equipment in cold weather conditions comes with its own set of challenges. EVAPCO has ample experience in such applications and can provide expert guidance to assist you.

March 9, 2023

EVAPCO, Inc. is thrilled to share the launch of its latest corporate video, "We Are EVAPCO," which showcases the remarkable growth of the company since its last corporate video release. We have expanded our global reach through strategic acquisitions, new plant construction, facility expansions, and entry into new markets. We take pride in presenting this growth story in our new corporate video and sharing it with our valued customers. At EVAPCO, our success is based on five core principles: dependable products, research and development, dedication to sustainability, a commitment to customer